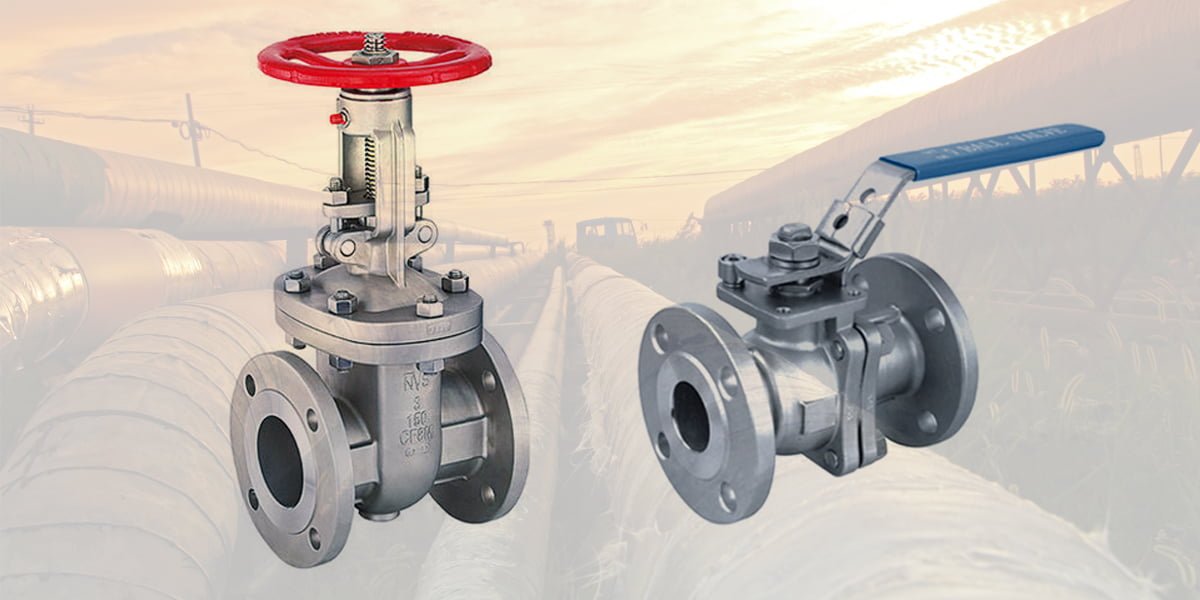

Ball Valve vs Gate Valve

In the world of industrial piping systems, many types of valves are used to control the flow of fluids, such as water, oil, gas, and chemicals. Two of the most common valves are ball and gate valves. Both types of valves are designed to control the flow of fluids, but they have different characteristics and applications. In this blog post, we will explore the differences between ball valves and gate valves and provide insights on when to use each type.

What is a Ball Valve?

A ball valve is a type of quarter-turn valve that uses a ball-shaped disc to control the flow of fluids. The ball inside the valve has a hole through the center. This ball allows the fluid to pass through when the valve is in the open position. When the valve is turned 90 degrees, the ball rotates to block the fluid flow. This feature makes ball valves easy to operate and can be used in manual and automated systems.

Ball valves are commonly used in applications where the fluid needs to be completely shut off or turned on quickly, such as in plumbing systems, chemical plants, and oil refineries. They are also resistant to high temperatures and pressures, making them ideal for use in applications where the fluid is under extreme conditions.

What is a Gate Valve?

A gate valve is a type of linear valve that uses a gate-shaped disc to control the flow of fluids. The gate inside the valve is raised or lowered by a threaded stem. A handle or an actuator turns this gate. When the gate is in the open position, the fluid flows through the valve unimpeded. The gate blocks fluid flow when lowered, preventing it from passing through the valve.

Gate valves are commonly used in applications requiring a tight seal, such as water supply, steam, and fire protection systems. They are also used in applications where the fluid needs to be regulated, such as in the oil and gas industry.

Differences between Ball Valves and Gate Valves

Design

Ball valves and gate valves have different designs. Ball valves feature a spherical ball with a hole through the center that rotates 90 degrees to open and close the valve. When the ball is rotated 90 degrees, the hole in the ball aligns with the inlet and outlet ports of the valve, allowing fluid or gas to flow through. When the ball is rotated back to its original position, the hole in the ball is perpendicular to the inlet and outlet ports, stopping the flow.

On the other hand, gate valves have a flat gate that slides up and down to open and close the valve. The gate is attached to a stem that moves up and down, allowing fluid or gas to pass through when the gate is lifted. When the gate is lowered, it creates a seal that stops the flow of fluid or gas.

Operation

Ball valves are operated by turning a handle or an actuator by 90 degrees, which rotates the ball inside the valve to control the flow of fluid. Gate valves are operated by turning a handle or an actuator to raise or lower the gate inside the valve.

Applications

Ball valves and gate valves are designed for different applications. Ball valves are typically used in applications requiring tight shut-offs, such as in natural gas pipelines, water treatment plants, and petrochemical plants. They are also used in applications where quick, precise control of the flow of fluid or gas is necessary. Ball valves are commonly used in low-pressure applications but can also be used in high-pressure applications.

In addition, Ball valves are commonly preferred in industries such as oil and gas, chemical, water treatment, and HVAC. They are used in applications requiring a fast and easy operation, high flow rates, and good shut-off capabilities. Ball valves are often used as isolation, control, and throttling valves.

On the other hand, gate valves are typically used in applications where a fully open or closed valve is required. These valves are commonly used in oil and gas, chemical, power generation, and water treatment industries.

Gate valves are used in applications requiring precise control, high temperature, and good shut-off capabilities. They are also used in applications where high-pressure and high-temperature fluids or gases are present. Also, just like ball valves, ball valves are often used as isolation, control, and throttling valves.

Flow Control

Ball valves are better suited for applications where the fluid needs to be turned on or off quickly. In contrast, gate valves are better suited for applications where the fluid needs to be regulated or shut off completely.

Sealing

Ball valves have a more reliable seal than gate valves due to their design. The ball in a ball valve creates a tight seal around the valve seat, preventing the fluid from leaking through. Gate valves rely on the compression of the gate against the valve seat to create a seal, which can be less reliable than the seal created by a ball valve.

Pressure and Temperature

Ball valves are better suited for high-pressure and high-temperature applications than gate valves. Ball valves can withstand pressures up to 1000 psi and temperatures up to 400°F, while gate valves can withstand pressures up to 500 psi and temperatures up to 300°F.

Advantages

Both ball valves and gate valves have their advantages. Ball valves are known for their excellent shut-off capabilities, making them ideal for applications requiring a tight seal. They are also easy to operate and require minimal maintenance. Additionally, ball valves have a compact design and are available in various sizes and materials.

On the other hand, gate valves are known for their ability to handle high-pressure and high-temperature fluids or gases. They are also reliable and durable, making them suitable for applications that require long-term use. Gate valves are also less prone to clogging compared to ball valves, making them ideal for applications where solids are present in the fluid or gas.

Conclusion

In conclusion, ball valves and gate valves are two different types of valves designed for different applications. Ball valves are best suited for applications requiring a tight shut-off and quick, precise control of fluid or gas flow. Gate valves, on the other hand, are best suited for applications requiring full opening or closing of the valve and high-pressure and high-temperature fluids or gases. Both valves have advantages, and the valve choice depends on the specific application and requirements.

It’s important to note that ball valves and gate valves have different designs and applications. They both play an important role in regulating the flow of fluids and gases in the plumbing and industrial sectors. Understanding the differences between these two types of valves will help you make an informed decision when selecting the appropriate valve for your specific application