Valve actuators serve as unsung workhorses in the realm of industrial automation. Performing the critical task of opening and closing valves, they provide the muscle for controlling the flow of fluids within a multitude of applications. In this guide, we’ll demystify the various types of valve actuators, enlightening you about their unique functionalities, advantages, and applications.

The Basics: Understanding Valve Actuators

In essence, valve actuators are devices designed to operate valves. They find their usage across a spectrum of industries, ensuring precision control over the fluid flow. This control is paramount in maintaining operational parameters like pressure, temperature, and level, thereby optimizing the overall process efficiency.

Order original AUMA actuators and parts from ProActuator

Do you need AUMA actuators or spare parts?

Diving Deeper: Exploring the Types of Valve Actuators

Valve actuators can be categorized based on their power source and mode of operation. Let’s explore these categories in detail.

Manual Valve Actuators

Manual valve actuators operate through direct human intervention. These actuators, leveraging the use of levers or handwheels, are a reliable choice for smaller applications where automation is not a requirement. Known for their simplicity and affordability, manual actuators, however, do not provide the scalability and precision offered by automated options.

Pneumatic Valve Actuators

Relying on air pressure to actuate valves, pneumatic valve actuators are a common sight in industries where a stable supply of compressed air is available. Their impressive reliability, rapid response time, and exceptional safety characteristics make them a preferred choice, particularly in hazardous environments where combustibility is a concern.

Hydraulic Valve Actuators

Harnessing the power of pressurized liquids, typically oil, hydraulic valve actuators shine in heavy-duty applications. These actuators offer high force output and stellar performance but require a hydraulic power unit, adding complexity and cost to the system.

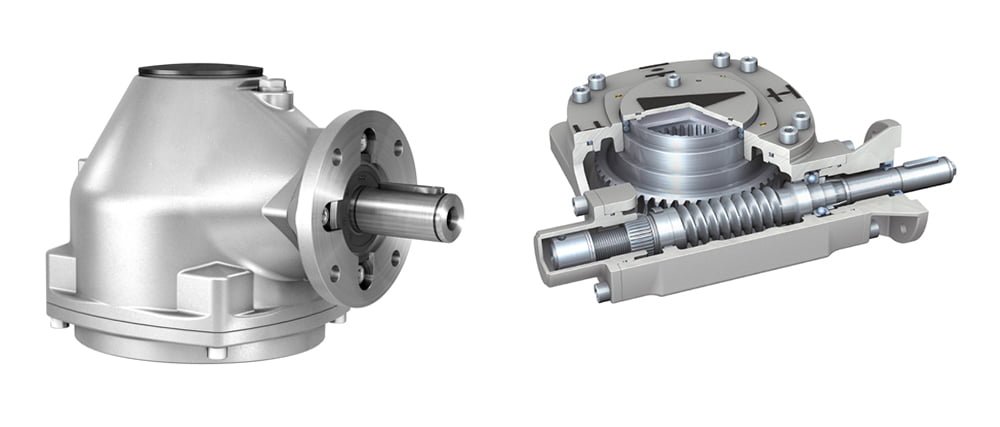

Electric Valve Actuators

Using an electric motor to drive valves, electric valve actuators are synonymous with precision and control. Thanks to technological advancements, these actuators now offer added benefits such as programmability and seamless integration with digital control systems. While operational costs may be a consideration, the rising focus on energy efficiency continues to address this challenge.

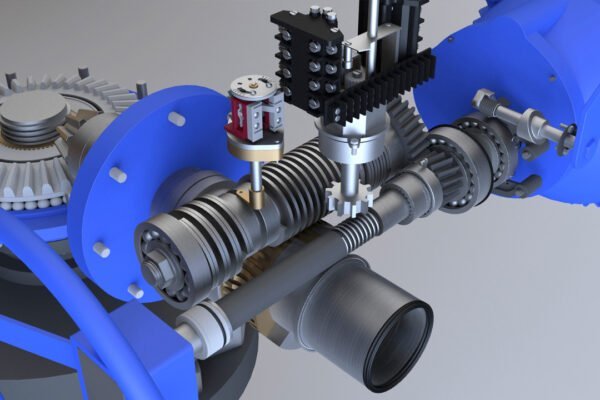

Electro-Hydraulic Valve Actuators

An innovative hybrid, electro-hydraulic valve actuators combine the best of electric and hydraulic types. Utilizing an electric motor to drive a hydraulic pump, they offer the accuracy of electric actuators with the power of hydraulic ones. While initial costs may be higher due to their complexity, the operational advantages often justify the investment.

Making the Right Choice: Selecting the Suitable Valve Actuator

Choosing the right valve actuator hinges on a variety of factors, such as the availability of the power source, environmental conditions, control requirements, and budget. Understanding the unique characteristics of each type of valve actuator can guide you in making a well-informed decision that suits your specific needs.

The Takeaway

The myriad of valve actuator types attests to the diverse needs of process automation. Whether it’s the simple manual options or the more sophisticated electro-hydraulic ones, understanding these types ensures effective application and enhanced process control. We hope this comprehensive guide empowers you to navigate the world of valve actuators with confidence, aiding you in choosing the perfect fit for your operations.