Electric actuator controls are an absolute necessity when it comes to managing valves in industries like oil and gas, water treatment, and power generation. Think of them as the trusted supervisors for your valves, ensuring they open and close accurately to keep fluid flow in check.

What are electric actuator controls?

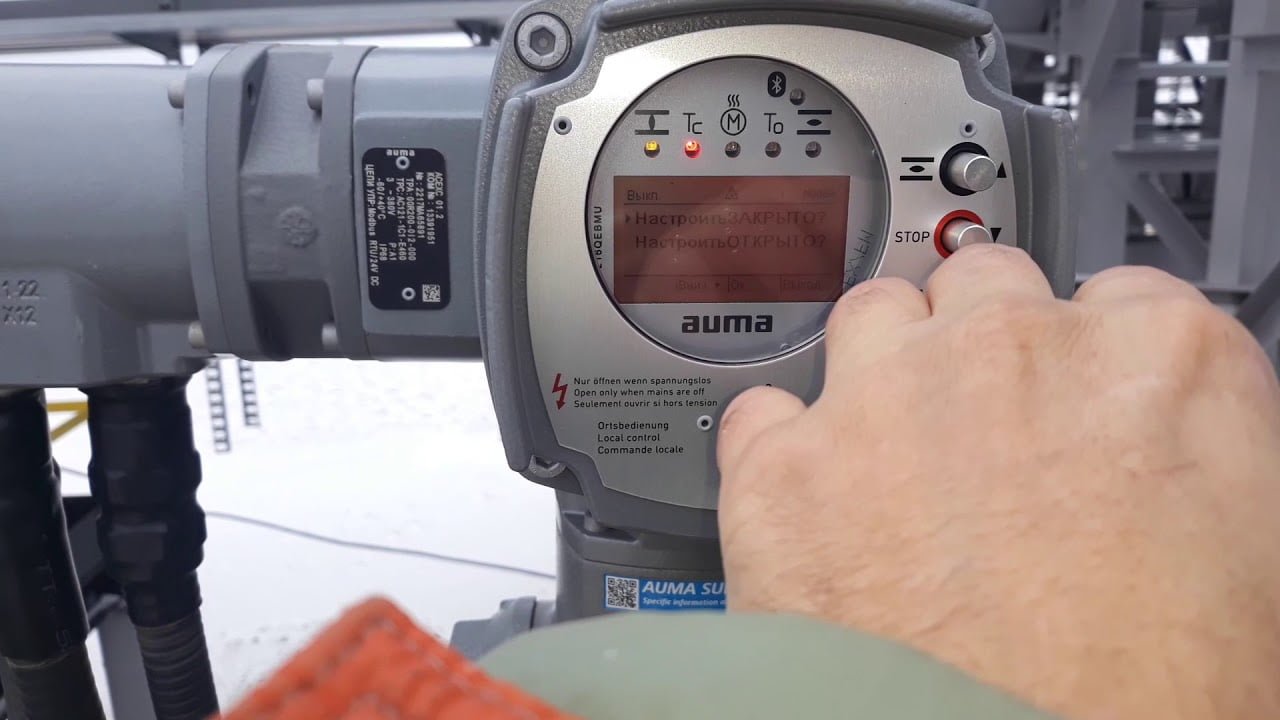

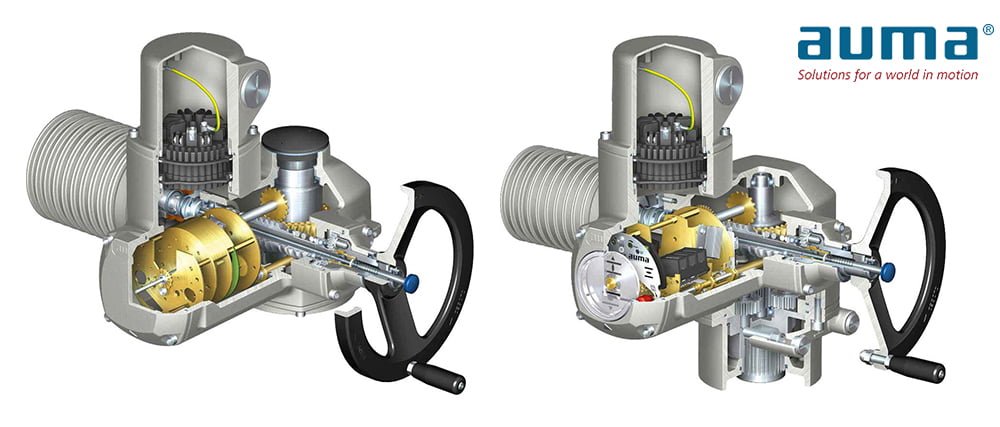

You might be wondering – what exactly are these electric actuator controls? Well, they’re devices that direct the movement of the electric actuator, adjusting the valve’s position as needed. The electric actuator is a clever little machine that turns electrical energy into mechanical motion, twisting the valve stem to open or shut the valve. The controls are like the brains of the operation, giving the electric actuator the instructions it needs to get the valve to just the right spot.

Importance of electric actuator controls

Actuator control units are seriously important when we’re talking about controlling valves, because they give us spot-on and trustworthy control. Getting the position of the valve just right is super important in loads of situations, like in the oil and gas world, where you’ve got to have the valve open or shut exactly when it needs to be, otherwise, you’re risking spills or even blowouts. What’s also impressive about these actuator control units is they let you control the valve remotely, so you can handle the valve operation without needing to be right next to it.

Features of electric actuator controls

Electric actuator controls come with a range of features, including:

- Limit switches: These switches limit the valve’s travel by stopping the electric actuator when it reaches a specific position.

- Position feedback: This feature provides feedback to the user about the valve’s position, allowing for precise control.

- Torque switches: These switches protect the valve from damage by stopping the electric actuator when it reaches a specific torque.

- Manual override: This feature allows the user to control the valve manually in case of an emergency or power outage.

Benefits of electric actuator controls

- Accurate and reliable control: Electric actuator controls provide accurate and reliable control of the valve’s position, ensuring safe and efficient operation.

- Remote operation: Electric actuator controls allow the valve to be operated remotely, reducing the need for manual intervention and increasing efficiency.

- Simplified maintenance: Electric actuator controls simplify maintenance by providing information about the valve’s position and condition, reducing the need for manual inspection.

- Cost-effective: Electric actuator controls are cost-effective compared to other types of valve controls, such as pneumatic or hydraulic controls.