- İvedik OSB - Ankara TURKEY

- trade@proactuator.com

Gearboxes

- Home

- Actuator Products

- Gearboxes

Actuators

Accessories

Spare Parts

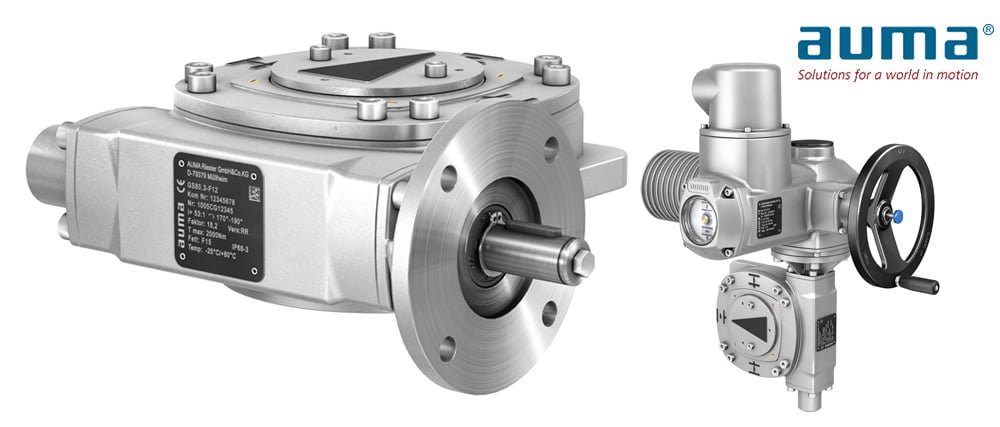

ACTUATOR GEARBOXES

All AUMA products and spare parts sold under ProActuator.com are original products manufactured by AUMA Riester GmbH & Co.

What is an actuator gearbox?

An actuator gearbox is a mechanical component that is used in electric actuators to increase the torque output and reduce the speed of the actuator. The gearbox is typically located between the electric motor and the valve stem, and its primary function is to transfer the rotary motion of the motor to the valve stem in a controlled manner.

An actuator gearbox typically consists of a series of gears that are arranged in a specific configuration to achieve the desired torque and speed reduction. The type of gearbox used in an actuator depends on the specific requirements of the application, including the torque output, the speed of the valve, and the type of valve being controlled.

Do you need AUMA gearboxes?

Product Line: Actuator Gearbox

Why do you need an actuator gearbox?

Actuator gearboxes can be integral with the actuator body or they can be separate components that are attached to the actuator. Integral gearboxes are typically more compact and cost-effective, while separate gearboxes offer greater flexibility and can be replaced more easily if they become damaged or worn.

In summary, the actuator gearbox is a critical component in electric actuators, and it plays an important role in ensuring that the actuator operates smoothly and efficiently. It is designed to increase the torque output and reduce the speed of the actuator, enabling it to control the flow of fluids and gases in various industrial processes.

You need actuator gearboxes in electric actuators for the following reasons:

- Increased Torque Output: Electric motors in actuators typically have a low torque output, which is unsuitable for controlling the flow of fluids and gases in various industrial processes. An actuator gearbox increases the torque output of the actuator, allowing it to effectively control the flow of fluids and gases in these applications.

- Reduced Speed: Electric motors in actuators typically rotate at high speeds, which can generate excessive noise and reduce the motor’s lifespan. An actuator gearbox reduces the speed of the actuator, reducing the noise generated and extending the lifespan of the motor.

- Improved Control: Actuator gearboxes enable precise control of the actuator, allowing it to open and close valves in a controlled and accurate manner. This is particularly important in applications where precise control of the flow of fluids and gases is critical.

- Increased Durability: Actuator gearboxes are designed to withstand harsh operating conditions in industrial environments. They help extend the electric motor’s lifespan by reducing the motor’s stress.

- Cost-effectiveness: Actuator gearboxes are a cost-effective solution for increasing the torque output and reducing the speed of electric actuators. They can be easily replaced if damaged or worn, reducing maintenance costs and downtime.

In conclusion, using an actuator gearbox in electric valve actuators is critical for ensuring that the actuator operates effectively, efficiently, and reliably. It enables precise control of the flow of fluids and gases in various industrial processes.