A valve actuator is an electromechanical device that controls valve opening and closing, typically used in precise fluid flow control applications.

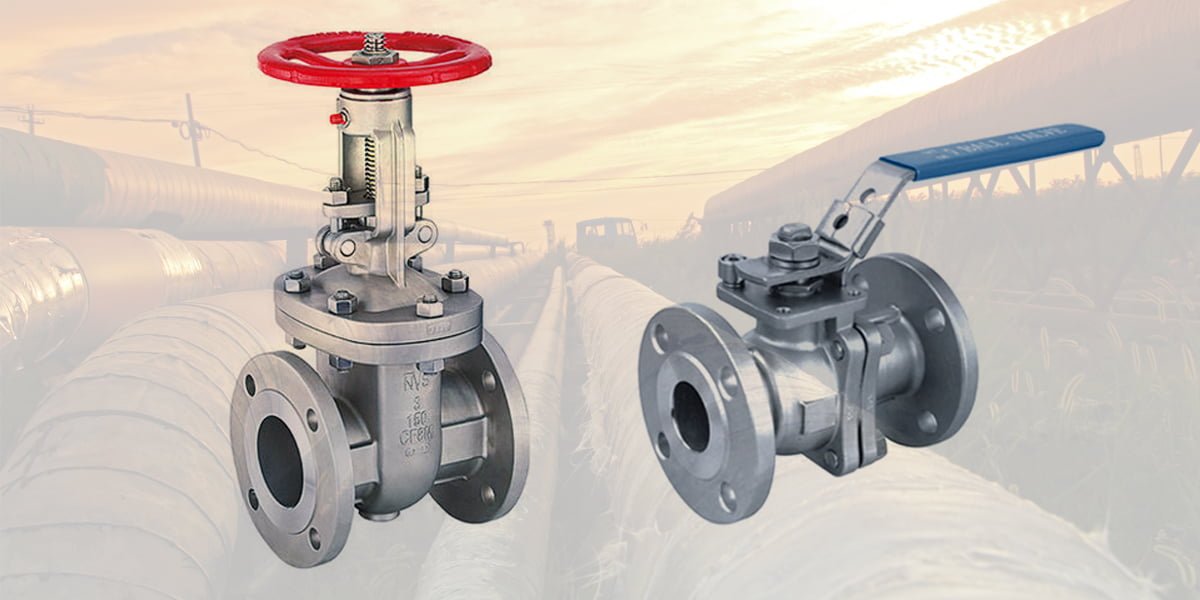

When controlling the flow of liquids and gases, there are two popular types of valves: ball valves and gate valves, each with unique features and benefits.

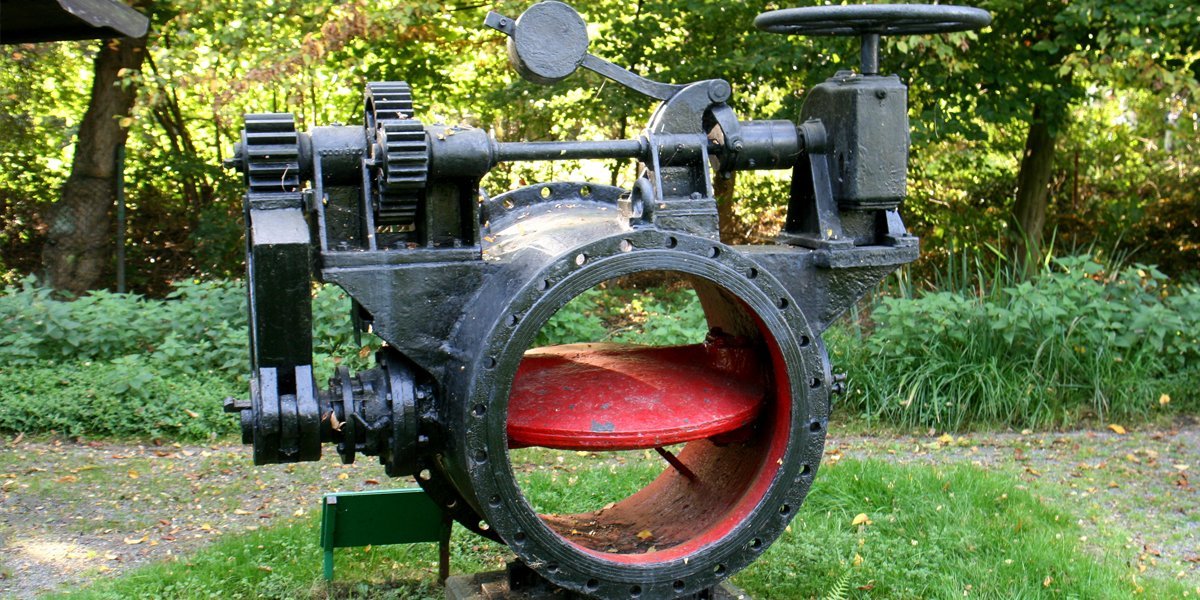

The principle of butterfly valves is based on the rotation of a disk that is positioned in the center of the valve body, which regulates the fluid flow.

A multi-turn actuator can provide rotational movement over multiple turns or rotations, making it ideal for applications requiring precise and repeatable positioning.

Globe valves are commonly used in a wide range of industries, including petrochemical, oil and gas, pharmaceutical, and water treatment.

Industrial valves and actuators work together to control the flow of materials, which is essential in maintaining the safety and efficiency of industrial processes.

Valve systems are critical components in various industrial processes, including chemical processing, oil and gas refining, and water treatment. The role of valves is to regulate the flow of fluids, gases, and other media, often at high pressure and temperature levels.