Actuators are devices that convert energy into motion or force. They play an important role in various industries, such as aerospace, automotive, and manufacturing. A multi-turn actuator can provide rotational movement over multiple turns or rotations, making it ideal for applications requiring precise and repeatable positioning.

Design and Operation of a Multi-Turn Actuator

Multi-turn actuators are typically powered by an electric motor. The electric motor generates the torque necessary to rotate the output shaft. The output shaft is connected to a gear train that increases the torque and provides the necessary rotation.

The gear train typically consists of worm gear or spur gear. Worm gears are often used in electric actuators, while spur gears are more commonly used in hydraulic and pneumatic actuators. Worm gears provide higher torque at lower speeds, while spur gears can provide higher speeds at the cost of reduced torque.

The gear train is connected to a position feedback system, which provides information about the actuator’s position. The position feedback system can be based on a potentiometer, resolver, or encoder. The feedback system is critical for ensuring the actuator’s position is accurate and repeatable.

Multi-turn actuator allows precise adjustment

Multi-turn actuators can provide rotational motion over several turns or rotations, which is ideal for applications that require precise and repeatable positioning. The number of turns or rotations that the actuator can provide depends on the design of the gear train and the motor’s torque. The maximum number of turns or rotations can vary between different types of actuators. Still, it is typically in the range of several hundred or even several thousand turns.

Applications of Multi-Turn Actuators

Multi-turn actuators are used in a wide range of applications in various industries. One of the most common applications is in the control of valves. Valves are used in many industries, including oil and gas, chemical processing, water treatment, and HVAC. A multi-turn actuator is used to open and close valves and adjust the valve’s position to control the flow of fluids.

In oil and gas applications, multi-turn actuators control the flow of oil and gas through pipelines. The actuator can be used to open and close valves to control the flow of the fluid, as well as to adjust the valve position to maintain a consistent flow rate. The feedback system on the actuator provides information about the valve’s position, which can be used to ensure that the valve is operating correctly.

In chemical processing plants, multi-turn actuators are used to control the flow of chemicals through pipelines. The actuator can be used to open and close valves to control the flow of the chemicals, as well as to adjust the valve position to maintain a consistent flow rate.

The feedback system on the actuator provides information about the valve’s position, which can be used to ensure that the valve is operating correctly.

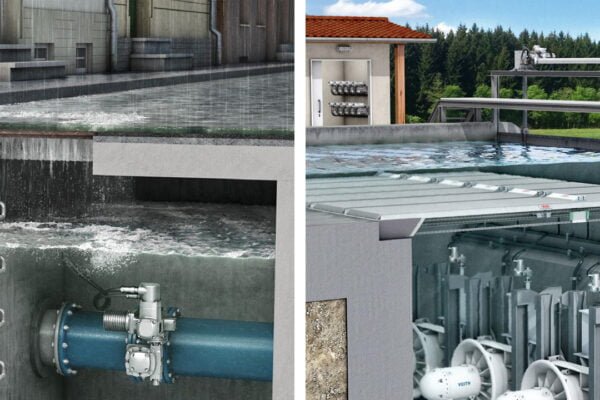

Water treatment and HVAC

In water treatment plants, multi-turn actuators are used to control water flow through a series of pipes and valves. The actuator can be used to open and close valves to control the flow of the water, as well as to adjust the valve position to maintain a consistent flow rate. The feedback system on the actuator provides information about the valve’s position, which can be used to ensure that the valve is operating correctly.

In HVAC systems, multi-turn actuators are used to control the flow of air through ducts and vents. The actuator can be used to open and close dampers to control the flow of air, as well as.